Maintenance Tips: Advice on Extending Undercarriage Life

March 28, 2014

Undercarriage wear and tear can be minimized and the key to reducing your undercarriage expenses is based on how you are able to manage wear and tear.

Extending Undercarriage Life

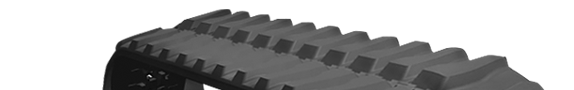

The undercarriage design of a vehicle is where some of the most essential parts and components of the machine are located. And being under the vehicle, it is also consistently subjected to abuse especially in extreme operating situations. The expected lifespan of a compact loader’s undercarriage is dependent on a number of factors. They include the way the vehicle is applied, the prevailing ground conditions, and your maintenance practices. This means that the life extension of a machine’s undercarriage and the cost of ownership are at the mercy of the one who operates the machine.

Conscientious operators know how to get the most performance out of a track loader and at the same time reduce the wear on the machine. Here are a few operating techniques that you can use to extend the life of your track loader, avoid expensive work downtime, and safeguard your investment.

Ground conditions

For an operator, it is essential that he understands the ground conditions and the way they affect the performance of a loader. One of the most common errors with track loader operation is the spinning of the tracks. This has always been a common practice with skid steers. However, track loaders have more than ample traction to fill the bucket with material without the operator needing to force it. Spinning the tracks, especially when the soil is loose, can cause a lot of pointless wear on the tracks themselves, including the undercarriage components. All of the mud, dirt, and other material get thrown up and they congeal onto the undercarriage parts. This causes more wear, and can have serious impact on the lifespan and performance of your machine.

At the same time, when working on hard surfaces like concrete and asphalt, you have to make wider three-point turns rather than counter-rotating the tracks. This will definitely help you minimize track wear and tear. Keep in mind that any form of aggressive operation will just increase the wear on the machine’s undercarriage. Yes, it would seem like you are speeding up the process but at the end of the day, it can also increase your cost of machine ownership because of the unnecessary maintenance expenses which could have been avoided if you just slowed a bit with the operation of the machine.

Rubber Tracks Plus - ABN: 80 155 770 415

37 Scammel St., Campbellfield VIC 3061

PH: 1300 820 214

Posts

2014

- Rubber Track Size - How To Find and Measure

- Comparison: Rubber Tracks and Steel Tracks

- How to Get the Most out of your Rubber Tracks

- Advantages of Steel Tracks

- Advantages of Rubber Pads for Steel Track Excavators

- Maintenance Tips: Advice on Extending Undercarriage Life

- What is a mini excavator?

- Getting Maximum Use from Your Mini-Excavator

- Choosing the Best Rubber Track

- Rubber Track Care: Maximise the Lifetime of Your Tracks

- Advantages of Rubber Skid Steer Tracks

2013