Rubber Track Care:

Maximise the Lifetime of Your Tracks

January 31, 2014

Following some basic measures can maximize the lifetime of your rubber tracks which will reduce down-time of your equipment and losing money that equipment may generate for you.

Working Environments and Operation

Avoid wear and damage to your track caused by working environments such as rocky terrain, gravel, concrete demolition, metal debris etc... The more careful the operator is when using rubber tracked equipment the better the track will fair in the long term. It is important to avoid exposure to contaminants such as salt or oil, however, if the tracks become exposed they should be cleaned off immediately.

Undercarriage Checks

Packing of soil and debris in undercarriage components can cause damage to the tracks. Packing prevents the proper engagement between the mating components such as sprocket teeth and track links. This can increase the load and stress on undercarriage components resulting in higher wear rates. Cleaning out the undercarriage as frequently as possible will help reduce possible issues with the tracks. Maintaining clean drive components avoids foreign substances from damaging the drive and track system. The tension of the tracks should be monitored on a regular basis as well.

What Causes Rubber Track Wear?

An undercarriage works as a system, thus, when a machine is in motion, there will be normal, unavoidable wear to the undercarriage and tracks. With proper undercarriage maintenance and operating techniques, the rate of wear can be reduced. Having the correct track tension adjustment is a critical factor to reduce undercarriage wear. Improper tension on tracks can increase wear up to 50%.

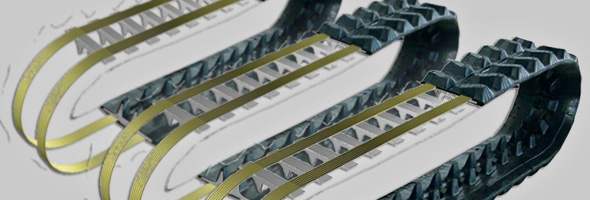

Using the right tracks

Selecting the narrowest tracks possible for your machine will optimise you machine's performance. Also, make sure they give you the floatation you need. Wide tracks used on hard surfaces will put an increased load on your machine increasing stress and loads on the idlers, rollers, and sprockets.

Alignment checks

Track frame and front idler misalignment will accelerate wear on all components. Check for track alignment by observing the wear patterns on the bottom rollers, carrier rollers, and front idlers. A visual inspection can also be done by just standing at the front and rear of the machine.

Contacting a professional for periodic checks on your machine will help to maximise your machine's rubber tracks saving you time and money. For any questions or concerns regarding your rubber tracks contact the professionals at Rubber Tracks Plus.Rubber Tracks Plus - ABN: 80 155 770 415

37 Scammel St., Campbellfield VIC 3061

PH: 1300 820 214

Posts

2014

- Rubber Track Size - How To Find and Measure

- Comparison: Rubber Tracks and Steel Tracks

- How to Get the Most out of your Rubber Tracks

- Advantages of Steel Tracks

- Advantages of Rubber Pads for Steel Track Excavators

- Maintenance Tips: Advice on Extending Undercarriage Life

- What is a mini excavator?

- Getting Maximum Use from Your Mini-Excavator

- Choosing the Best Rubber Track

- Rubber Track Care: Maximise the Lifetime of Your Tracks

- Advantages of Rubber Skid Steer Tracks

2013